Aluminum is an old favorite material used by window frames because of its strength and durability and smooth modern look. Nevertheless, it has been considered a major setback regarding energy efficiency due to its great capability in heat conducting. This is where the thermal break technology lies in and changes the performance of the aluminum windows. This article describes the concept of this innovation and the ways in which it makes the experience of a building way more comfortable.

Introducing the Principle of Thermal Insulation

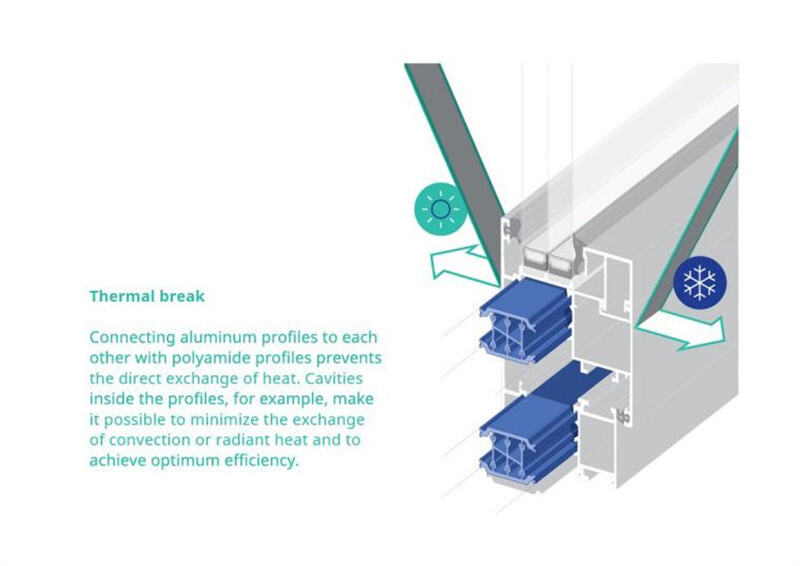

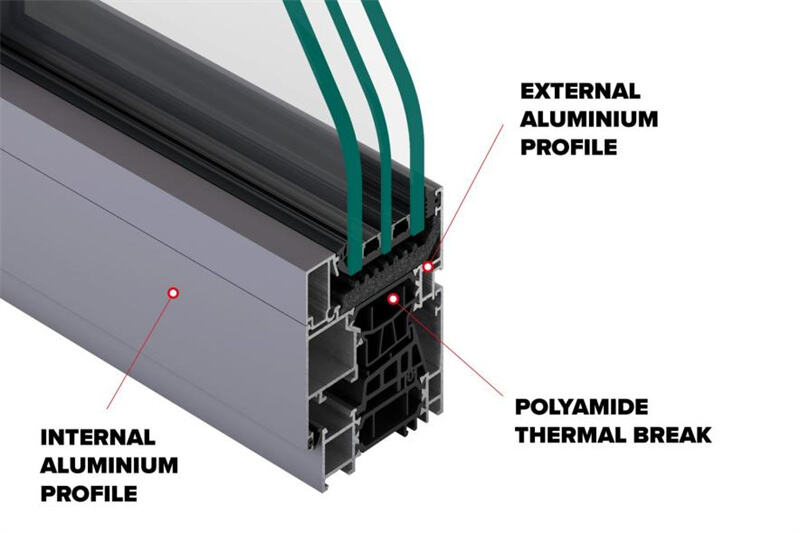

A thermal break is in essence, an element installed in between the aluminum window frame. Take the case whereby the aluminum frame is divided into an outside and an inside part. These two parts are not separated by a thermal break, and thus form a free flow of heat in between the interiors and the exterior of the house.

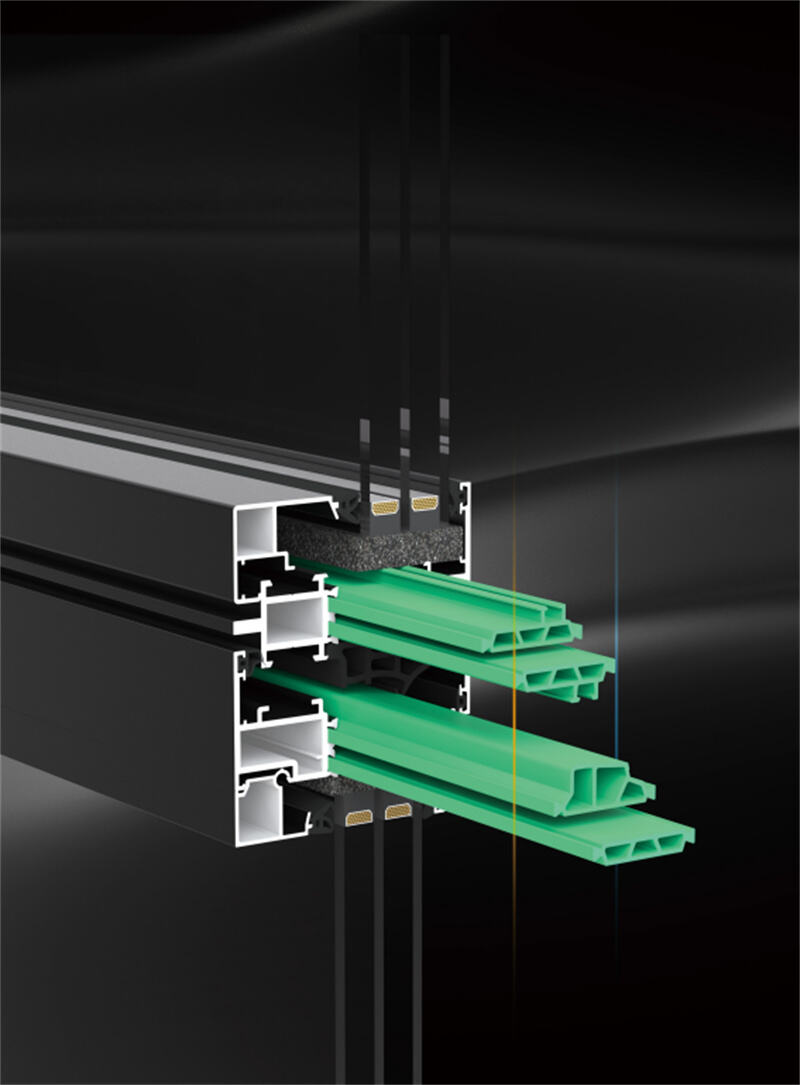

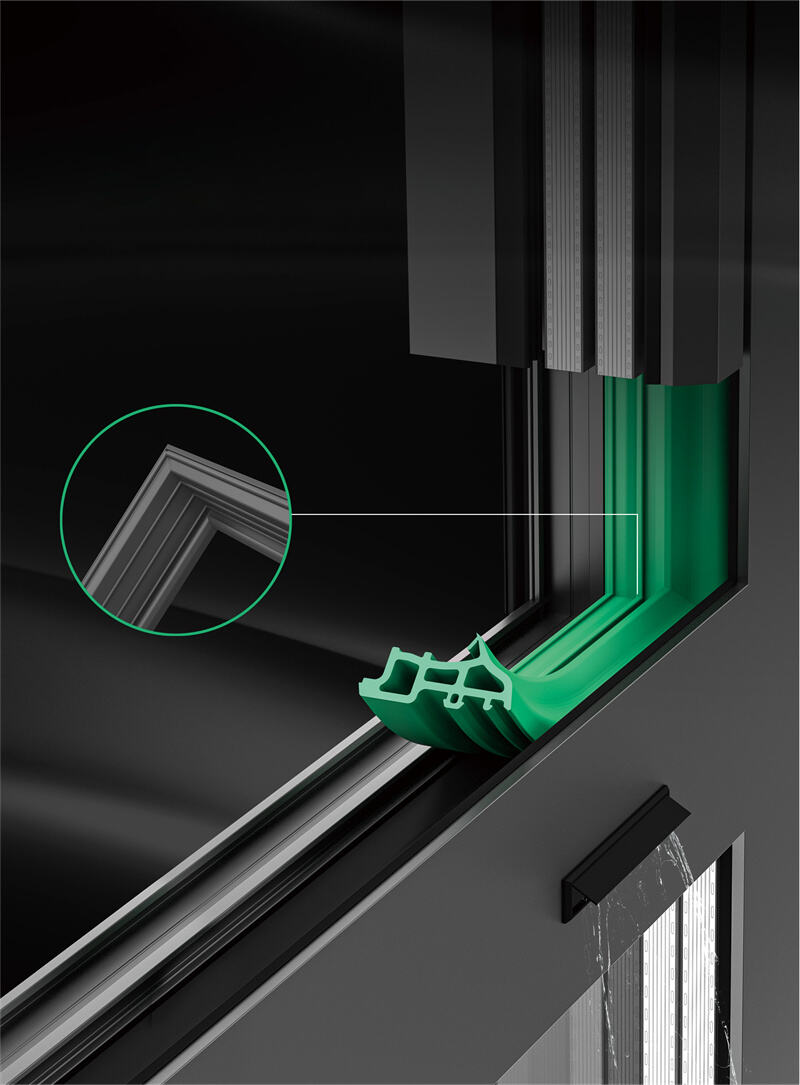

Thermal insulation consists of breaking this path. In thermally broken window framing, a low-conductivity, very durable material is used in bridging the gap between the inner and exterior aluminum profiles. This is such a barrier that the two parts of aluminum do not touch each other. In so doing, it works wonders in lowering the transfer of thermal energy therefore, indoor temperatures remain constant during different weather conditions.

How Thermal Insulation Strips Reduce Heat Conduction

The movement of thermal energy in a solid material is known as heat conduction. Aluminum is an excellent conductor, i.e. it easily permits heat through. The frame behaves as a highway to heat loss in winter and heat gain in summer in a non-thermal break window.

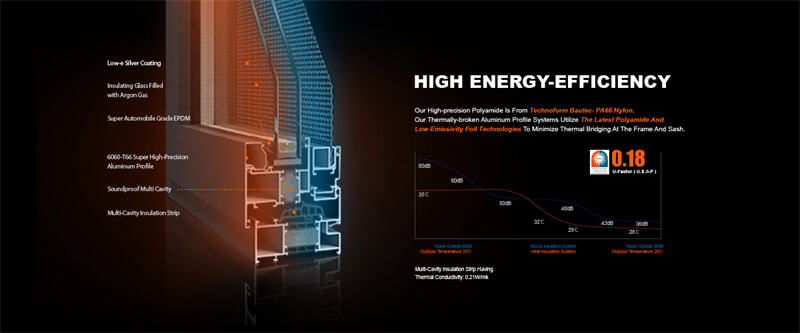

The thermal resistant strip serves as a highway block on this road. The strip is composed of low thermal conductivity materials including polyamide (extremely strong engineering plastic), which poses a barrier that heat finds it difficult to penetrate. The reason behind this is that the thermal energy will not be transmitted almost as effectively by the molecular structure of the polymer as it would be by aluminum. The consequence is that the amount of heat conduction through the frame itself will be drastically reduced. The insulation strip makes the interior frame to stay nearer to the interior temperature where the cold feel during winter and the hot-to-the-touch feel during summer are removed, so the general comfort is improved.

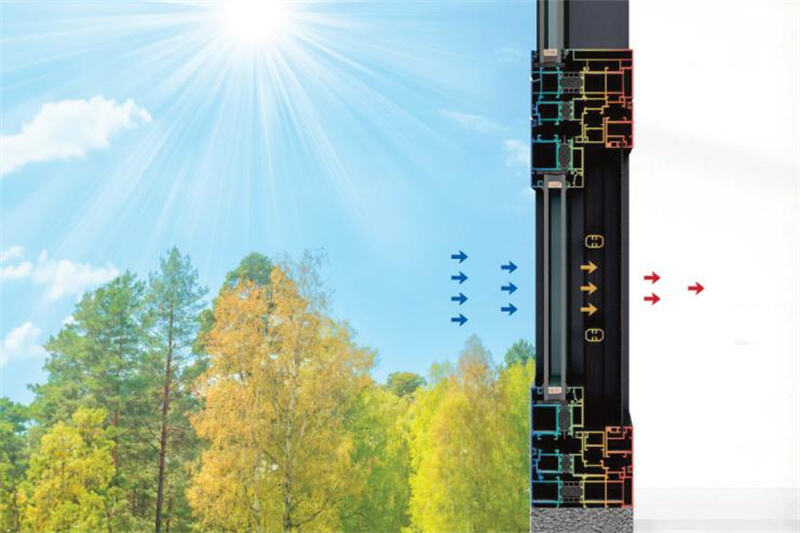

Significant Effects on Winter Heat Preservation and Summer Heat Insulation

The advantages of this technology are the most obvious when it comes to their direct effect on your living conditions and your yearly energy bills.

In winter, even traditional aluminum windows may feel chilly indoors where the chilly winter has been passed on through the frame. The result of this is quite often heat loss, cold drafts, and condensation. This is blocked by thermally broken windows. The inside frame is warmer and much less condensation does occur; the inside surface is also more comfortable. Your heating system does not need to work extra hours to achieve the same amount of heat loss through the frames thus saving a lot of energy.

The same effect is impressive in summer. The heat outside is prevented to be conducted inside the frame. This improves the ability to keep the interior cooler, decreases the amount of strain on your air conditioning system, and enhances overall comfort by ensuring that the interior frames do not get unpleasantly hot. Through its protective role against external temperatures throughout the year, thermal break technology is a basic characteristic of an energy-saving and cozy modern construction.

EN

EN

FR

FR

DE

DE